Six months ago I was looking for a small, light weight camera to make another one of my smaller planes into a FPV platform.(First-Person Video) While shopping I was pleasantly surprised at how the cost and weight of the airplane side components had dropped from when I first started dabbling in FPV.

It was now cheap to put together a system; however none of my friends were flying FPV. What was stopping them?

I decided that if the cost of the system was low, then the remaining barriers to entry would be:

Not knowing it was cheap/possible

Not knowing how to put together a system.

I wanted to change that!

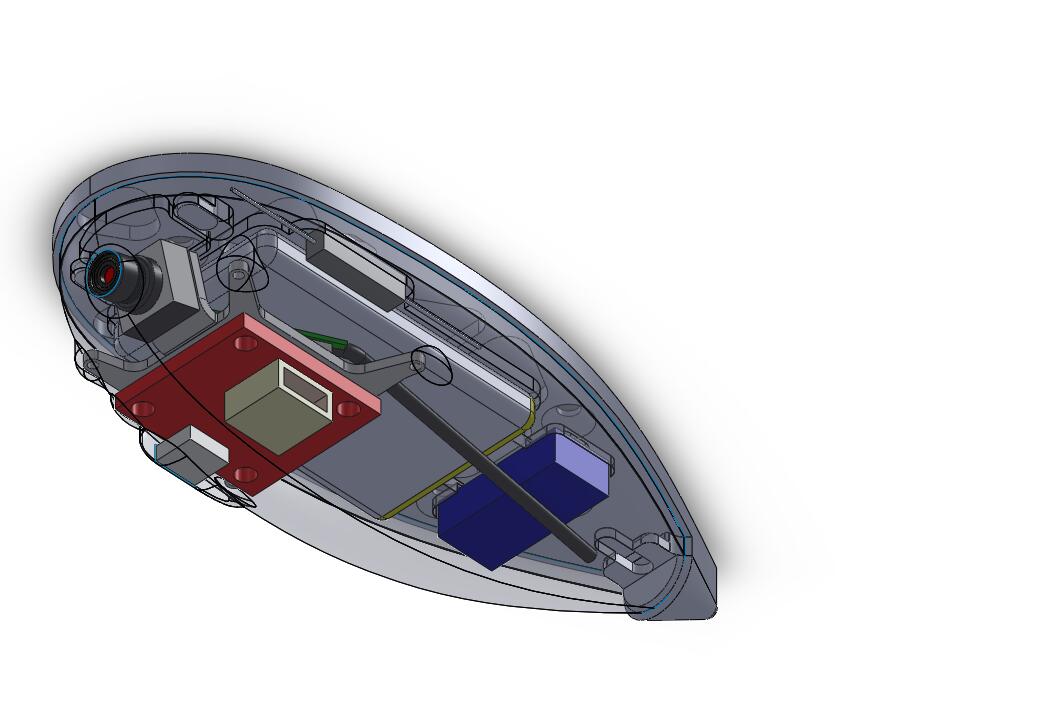

When I tell people about the Fly-Sight, my elevator speech is that it removes the ‘science-fair project’ part of assembling an FPV system, instead of choosing components piecemeal and assembling you can buy a proven set of components pre-assembled.

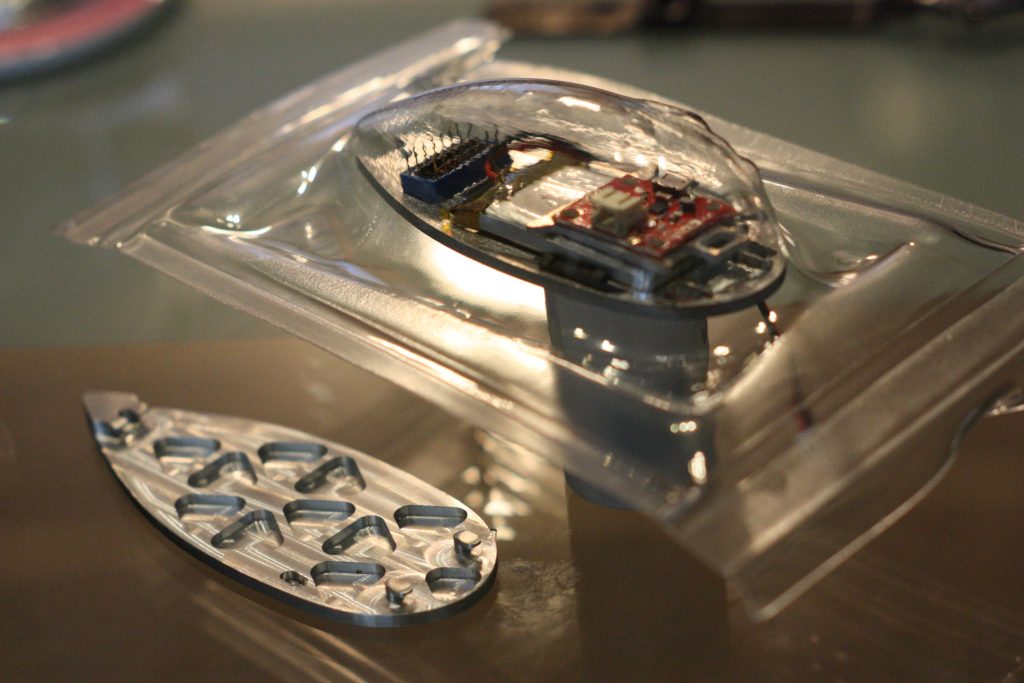

My first design used a lot of off the shelf electrical components, as I didn’t have much electrical knowledge at the time. In hindsight I should have started by cracking the books first.

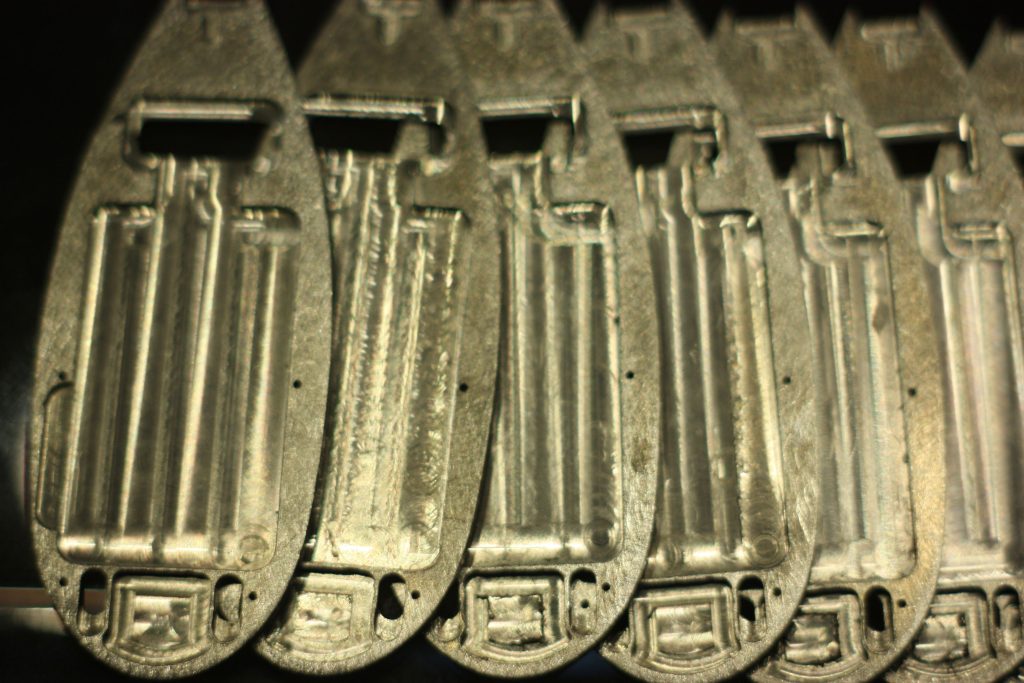

With the first few articles flying test flights, problems showed up quickly:

The first, was that the off the shelf battery charger/voltage controller board wasn’t able to meet its advertised current flow. The first Fly-Sights would brown-out often.

After that was fixed, I was having problems with the wires soldered onto the transmitter breaking off their pads, the whole assembly was fragile until the shell was in place. I ruined a few while making them.

Then the reed switch would weld itself together, causing the Fly-Sight to turn on once it was mounted, as desired, but failing to turn off. I could pound the Fly-Sight on a table to shake the contacts apart, but, that would usually cause a pad on the transmitter to break off.

Clearly this would be no good to offer for sale. (However if you want some of the excess parts, send me an e-mail and I’ll throw them in with your order. The first orders will get the transmitters, which can be made to work with some soldering iron time.)

Despite all those failings the core of the idea was very good. What stayed from this design was; mounting with double sided foam tape, having the Fly-Sight turn itself on only when mounted, having a dedicated on-board battery and charger, and general packaging of components.

V2 was designed to fix all those problems . . .